top of page

INFRARED ELECTRICAL INSPECTIONS

FIND HOT SPOTS

AVOID UNSCHEDULED MAINTENANCE

REDUCE DOWN TIME

INCREASE SAFETY & PROFITS

1/3

INFRARED ELECTRICAL INSPECTIONS

-

FIND HOT SPOTS

-

AVOID UNSCHEDULED MAINTENANCE

-

REDUCE DOWN TIME

-

INCREASE SAFETY & PROFITS

1/3

1/3

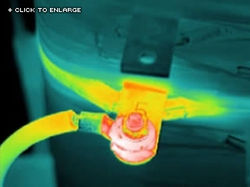

Detect system overloads, loose defective components and damaged switchgear. Infrared electrical testing finds hot, dangerous problems quickly.

Because increased heating is a sign of failure, infrared is the best diagnostic tool available for finding these hot connections in the early stages of degeneration. This is why your insurance company may have asked for an electrical infrared inspection, to find and prevent problems before they cause damage to your personnel, equipment and facility.

On-site inspections and Lug Nut Maintenance repairs done concurrently saving time and money.

*Disclaimer: If power has to be shut down at site, repairs will be done at a later date.

In electrical systems increased resistance can be caused by component age, fatigue, oxidation, wear, loose connections or poor installation.

Even new components can be defective

Electrical Infrared Surveys Improve Safety, Reliability & Reduce Down Time

Infrared electrical inspections performed per NFPA and insurance company recommendations can detect and document incipient failures and should be combined with timely, effective repairs.

|  |  |  |

|---|---|---|---|

|  |  |  |

|  |

bottom of page